Choosing between semi-auto and automatic stretch wrapping machine

Choosing between semi-auto and automatic stretch wrapping machine

Blog Article

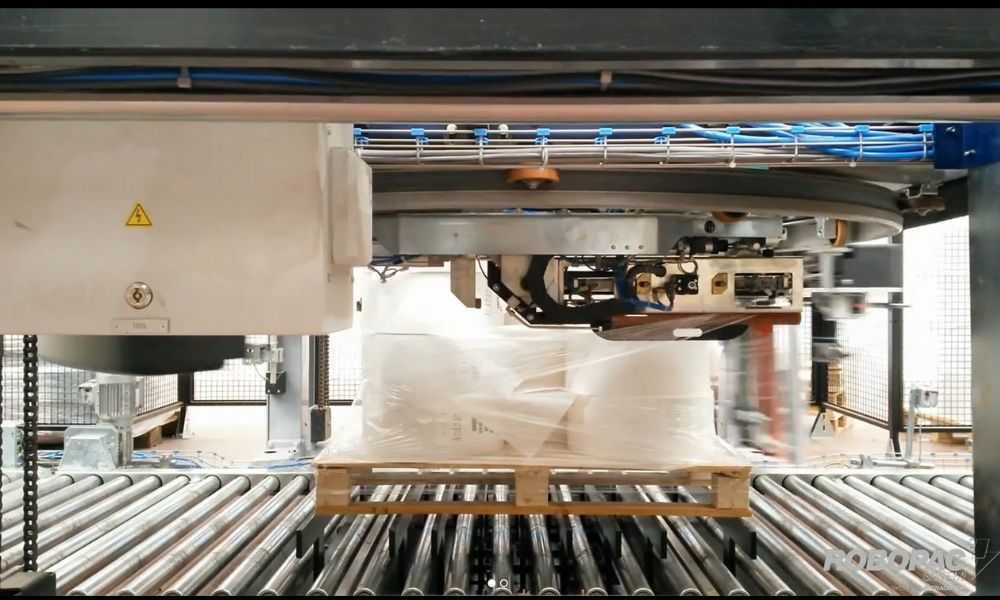

Unleash Performance in Your Warehouse Operations With a Premium Stretch Covering Device

Productivity in stockroom procedures rests on the performance of the product packaging process. The intro of a premium stretch covering maker can be a game-changer, appealing effectiveness, lowered labor expenses, and decreased human mistake. With the capability to take care of different lots dimensions and cover many pallets per hour, these machines use an engaging proposal for any kind of organization seeking to optimize its operations. So, what makes these makers such a vital property in warehousing? Let's discover even more.

Comprehending the Role of Stretch Covering Machines in Storehouse Workflow

In the large world of stockroom operations, the importance of stretch wrapping devices can not be overemphasized. They offer an essential duty in making certain that products are securely and firmly packed for storage space or transportation. These machines use a very stretchable plastic film around things, securely covering them with each other in a way that manual covering merely can not match.

Stretch wrapping makers can deal with huge volumes of items promptly, dramatically speeding up the packing procedure. The consistent wrapping supplied by these makers can reduce the threat of tampering or theft throughout transit.

Key Functions of High-Quality Stretch Covering Machines

While there is a variety of stretch covering equipments offered in the marketplace, top quality models share certain crucial features that establish them apart. These machines are typically durable, designed to hold up against significant use without compromising on performance. They supply a high level of automation, allowing for efficient and problem-free covering of items.

High-grade stretch covering machines also include flexible setups, providing flexibility to suit numerous packaging needs. They can manage different dimensions and kinds of loads, making certain a safe wrap each time. These machines are likewise renowned for their rate, capable of covering countless pallets per hour, therefore significantly boosting productivity.

Another trick attribute is their reliability and low upkeep need. High-grade makers are developed to last, decreasing the regularity of breakdowns and the associated downtime. In addition, they run with accuracy, making sure regular wrap tension, therefore lowering waste and improving the presentation of covered products.

The Effect of Stretch Covering Devices on Stockroom Efficiency

The effectiveness of a storehouse can be dramatically improved with the use of high-grade stretch covering makers - stretch wrapping machine. These devices streamline the product packaging procedure, decreasing the manual work entailed and as a result, the opportunity for human mistake. This guarantees a more constant and dependable wrapping procedure, causing enhanced safety of items during transportation

In addition, stretch wrapping machines can deal with a greater volume of items in a shorter amount of time contrasted to manual covering. This increased performance can lead to far better application of stockroom area as items can be packaged and relocated faster. The devices also supply the versatility to accommodate different shapes and sizes of products, further enhancing operational efficiency.

Calculating the Return on Investment for a Stretch Wrapping Maker

Considering the substantial benefits of stretch covering machines, it's important to comprehend the monetary ramifications of purchasing such devices. The return on financial investment (ROI) estimation is a basic yet effective tool to analyze the profitability of this investment. The ROI is computed by comparing the expense of the equipment with the cost savings created over a particular period.

The greater the ROI, the extra successful the investment. However, this number should not be the sole factor in the decision-making process. Services need to also take into consideration variables such as calculated placement, operational performance, and scalability. Finally, determining the ROI gives a clear financial viewpoint to direct the investment decision in stretch wrapping devices.

Real-world Situation Research Studies: Success Stories of Executing Stretch Covering Machines

Attracting from the monetary implications talked about in the previous section, it is similarly enlightening to analyze functional applications and success tales of companies that have implemented stretch wrapping equipments in their procedures. One such example is a multinational electronic devices company which reported a 30% decrease in harmed goods during transit after presenting stretch wrapping makers in their product packaging procedure.

An additional success tale involves a leading food and drink company. After applying a stretch covering maker, they observed a considerable enhancement in their product packaging rate, which consequently enhanced daily results and general productivity.

Last but not least, a popular furniture supplier was browse around this site able to lower their packaging material costs by an incredible 40% after switching to extend wrapping devices; they simultaneously minimized their carbon footprint, making their operations much more lasting. These real-world study show the remarkable returns and performance gains that stretch wrapping devices can offer storehouse procedures.

Final thought

To conclude, spending in a high-quality stretch wrapping equipment can substantially enhance warehouse procedures. With its capability to decrease manual work, minimize mistakes, and boost space utilization, it significantly enhances productivity and profitability. The ROI, coupled with success stories from real-world executions, better emphasizes the important duty of stretch wrapping devices in attaining functional effectiveness and business success.

The introduction of a high-quality stretch covering maker can be a game-changer, promising performance, lowered labor costs, and decreased human error.In the substantial world of storage facility operations, the relevance of stretch wrapping equipments can not be overemphasized.The performance of a stockroom can be substantially boosted with the use of high-grade stretch wrapping equipments.Furthermore, stretch covering devices can handle a higher Full Report quantity of items in a much shorter quantity of time compared to hands-on wrapping.In conclusion, spending in a high-quality stretch wrapping device can substantially enhance storage facility operations.

Report this page